Years of Experience in Machined Parts Manufacturing

Years of Experience in Machined Parts Manufacturing

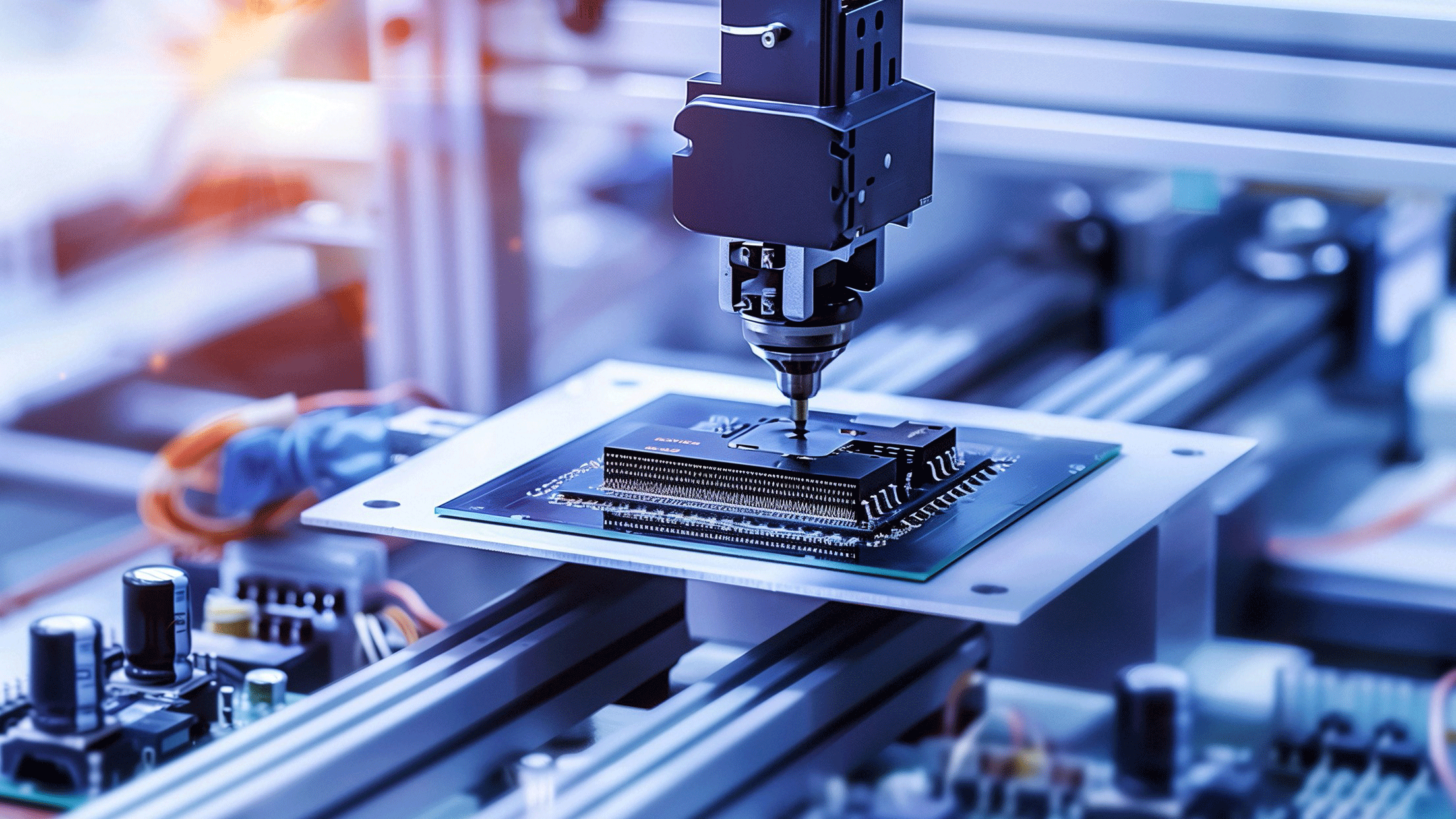

Comprehensive equipment and processes

We are equipped with a wide range of advanced machinery, including turning, milling, grinding, drilling, and CNC machining, providing full-process coverage. Whether for simple parts or complex structures, we offer one-stop solutions to meet diverse machining needs, ensuring both product quality and production efficiency.

High precision up to 0.005 mm

Utilizing advanced high-precision CNC machines and a rigorous inspection system, we achieve critical dimensional tolerances of ±0.005 mm, meeting the stringent accuracy standards required by high-end fields such as precision instruments, medical devices, and optics.

Small-batch manufacturing

Breaking traditional batch limitations, supporting single-piece customized production, eliminating the need for inventory, and reducing trial-and-error costs. From sample validation to small-batch requirements, we flexibly handle orders to help streamline your R&D and production processes.

5–10 day rapid delivery

Streamlined production processes and a dedicated professional team enable standard parts to be delivered in as fast as 5 days, with rush orders prioritized for expedited processing. Reduced lead times to help you respond quickly to the market and seize new opportunities.

Product Cases

Why Choose Us?

Our Commitment

Choose us with confidence

every micron is a promise

Representative Clients

News

Research on Manufacturing Process and Precision Machining Technology of Automotive Machinery

In the constantly developing economy, the Chinese automotive industry is facing some opportunities and challenges. For example, the application of new manufacturing processes and processing technologies can bring opportunities for the development of the automotive industry, but at the same time, the automotive industry will also face severe market challenges.

What is the difference between casting and machining

In the field of industrial manufacturing, casting and machining are two indispensable processes. They play a key role in the production process of products, but there are significant differences in their characteristics, process flow, and scope of application. Understanding the difference between casting and machining is not only crucial for engineers and related practitioners, but also helps companies make more informed decisions when choosing production processes. This article will conduct an in-depth analysis of these two processes, exploring their respective advantages, disadvantages, and application scenarios.

Comprehensive analysis of powder metallurgy gear manufacturing process

This article provides a comprehensive analysis of the manufacturing process of powder metallurgy gears, covering raw material selection, compaction, sintering, and post-processing. It elaborates on the process advantages, application fields, and development prospects.

Is casting processing cheaper than machining

Casting and machining are two common processing methods in the manufacturing industry, each with its unique advantages and application areas. Choosing the appropriate processing method not only affects production efficiency, but also directly relates to cost control. In this article, we will delve into whether casting processing is more economical than machining, as well as the various factors that affect the cost of both.