OEMACH TECHNOLOGY CO., LTD.

Capable of handling machining tasks with various process requirements, including turning, milling, grinding, wire cutting, EDM, laser welding, internal and external cylindrical grinding, four-axis and five-axis CNC, and 3D printing equipment. Component precision can reach 5 μm. 3D printing supports a wide range of materials, including metals, ceramics, and plastics.

Able to meet machining needs for a variety of materials: plastics, aluminum, stainless steel, copper, titanium alloys, ceramics, nickel alloys, magnesium alloys, and other rare metal alloys.

Able to provide a wide range of surface treatments, including anodizing, electroplating, spraying, sandblasting, polishing, and plasma surface engineering (including physical vapor deposition, chemical vapor deposition, and ion nitriding)

Capable of fulfilling industrial design requirements

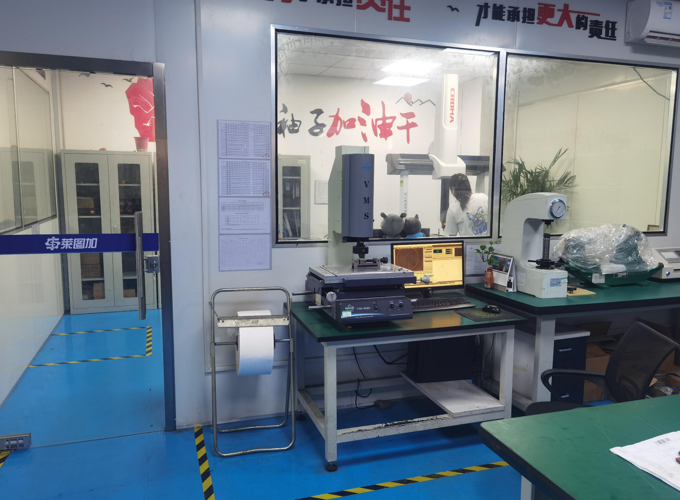

Factory Environment

Precision Quality Inspection

Full inspection with coordinate measuring machines and complete process traceability, with a defect rate of less than 0.03% to ensure quality.

Constant Temperature Manufacturing

Controlled humidity at 23 ± 1°C and anti-static flooring to guarantee micron-level machining accuracy for precision parts.

Production Workshop

4,000 m2 production facility equipped with over 40 imported machines, intelligent manufacturing, and precision machining accuracy up to ±0.005 mm.

Intelligent Management

MES system for visualized control, flexible production lines for rapid switching, and order delivery times reduced by 30%.

Tech Team

Engineer Yan - Process Engineer

Specialty:

Solutions for machining parts with complex structures; process matching; application of special machining techniques; design and manufacturing of complex components; assembly and tolerance control.

Introduction:

With deep expertise in the field of machining, he has led hundreds of custom projects involving complex automotive and aerospace components, innovating process matching and design for manufacturability, precisely controlling tolerances to ±0.01 mm, achieving a product qualification rate of 99.5%, and enhancing enterprise competitiveness.

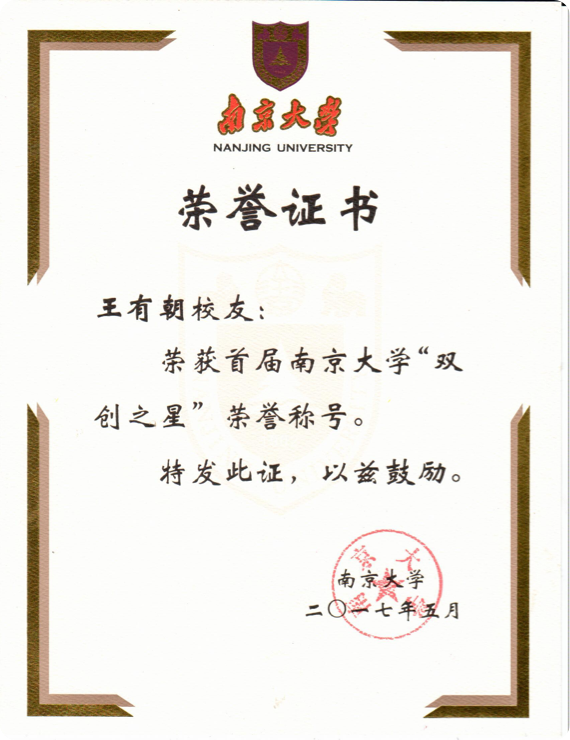

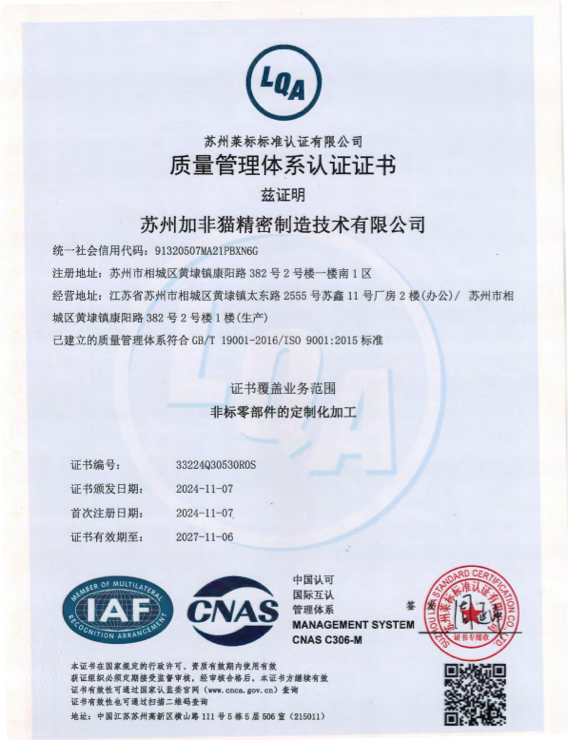

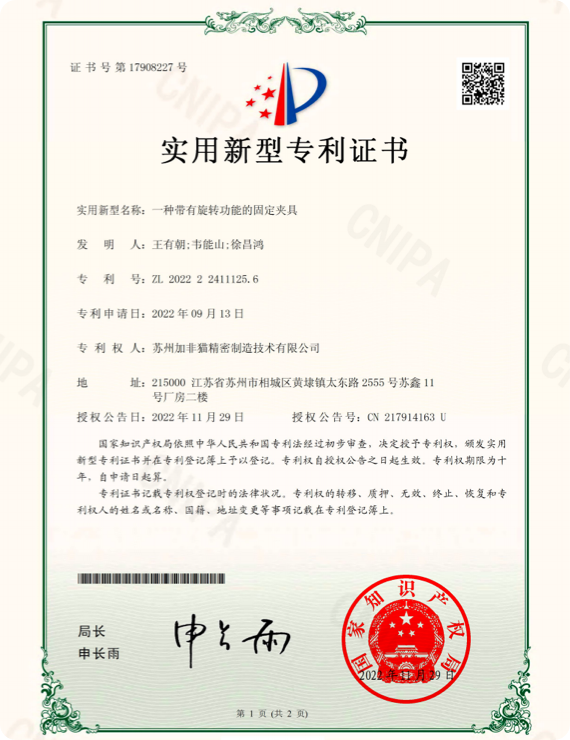

Certifications & Honors

Engineering Excellence, Smart-Certified

OEMach: Patented Technology + Authoritative Certifications, Guarding Your Quality.

National High-Tech Enterprise

2024-12-04

"Innovation and Entrepreneurship Star" of Nanjing University

2017-05-05

Quality Management System Certification

2024-11-15

Utility Model Patent Certificate

2022-11-02

Selected Entrepreneur of the Xiangcheng District Science and Technology Leading Talent Program

2022-07-02

Vice President Unit of Xi'an Jiaotong University

2019-01-09

Privacy Policy

"Disclaimer: Before registering as a member and using our services, please carefully read the following terms. In these terms, 'you' and 'your' refer to the user, while 'we', 'us' and 'our' refer to this website."

Frequently Asked Questions