Medical

Service Overview

As the medical device industry continues to flourish, OEMach, as a professional provider of medical device parts machining services, remains committed to building a solid safeguard for health and wellness through exceptional product quality. We have cultivated deep expertise in the field of precision mechanical parts machining, leveraging advanced CNC machining technologies and high-precision equipment to establish a rigorous and comprehensive quality management system. In response to the medical device industry’s demand for a wide variety of products in small batches, we provide customers with one-stop, full-spectrum services covering everything from R&D and design to large-scale production.

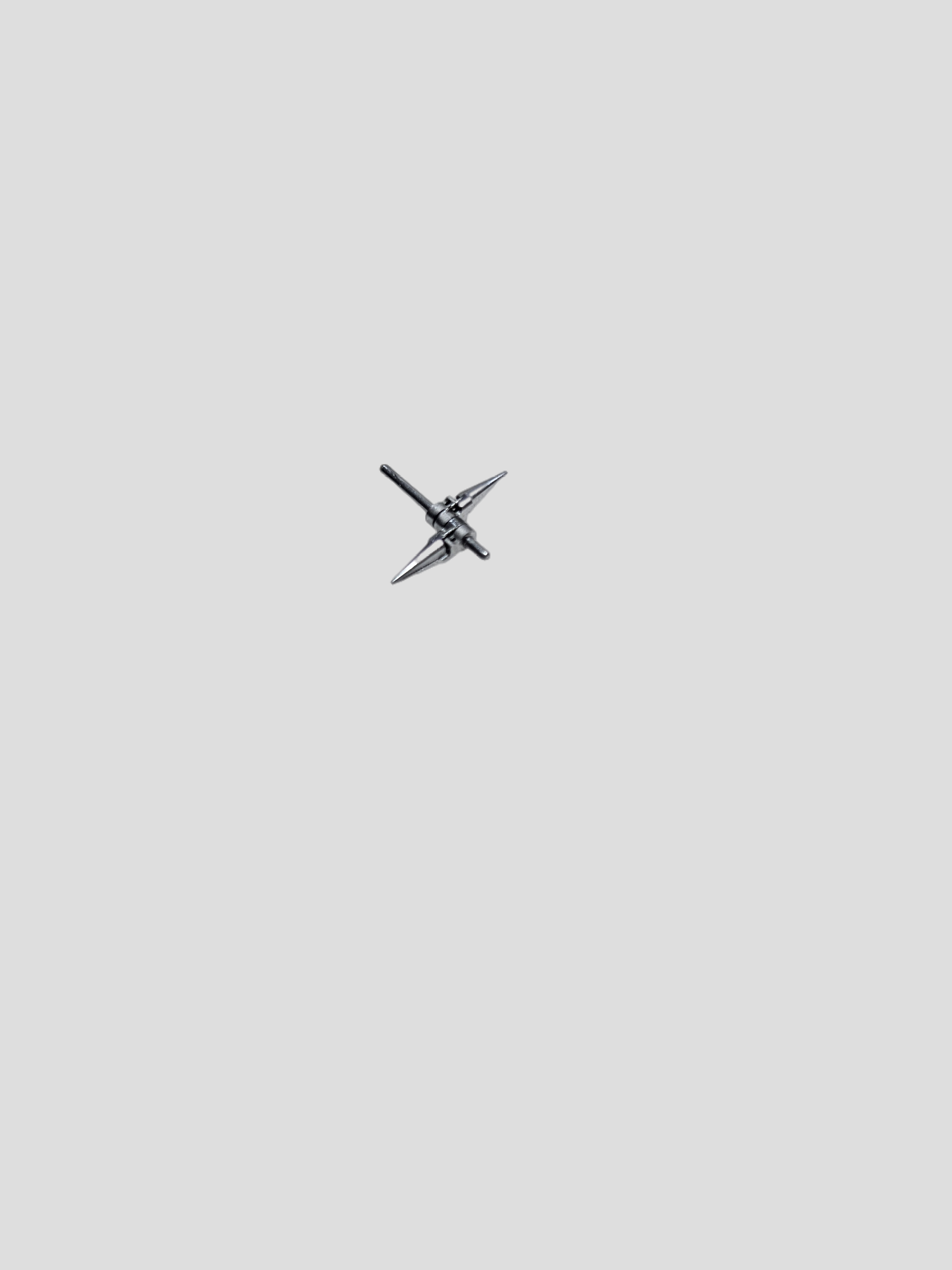

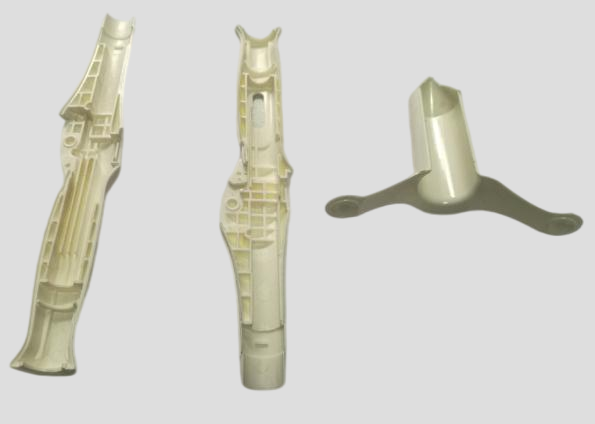

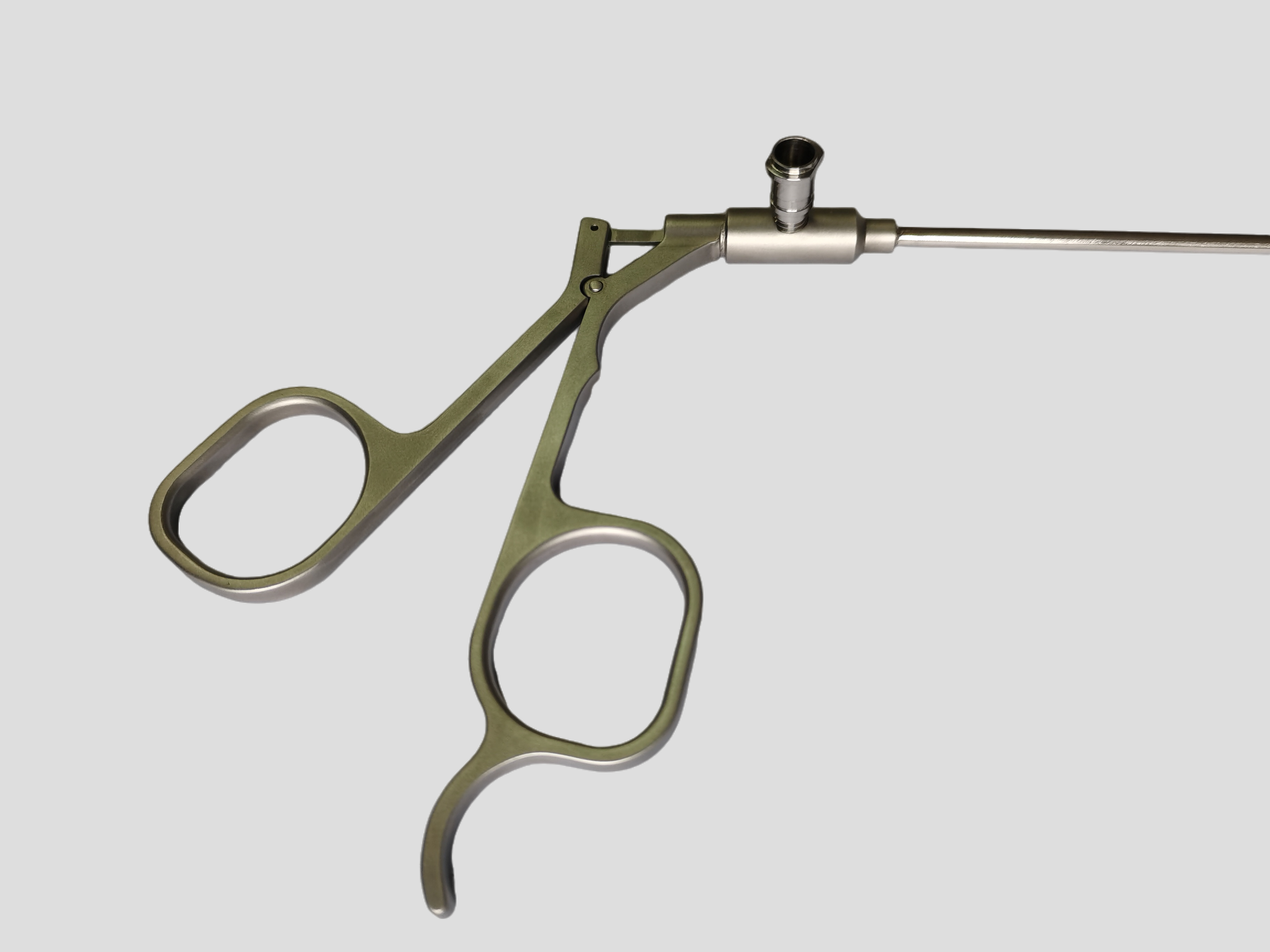

Whether it is high-precision surgical instrument components—such as scalpel blades and endoscope biopsy channels—or complex structural parts for medical equipment, including core drive components for CT scanners or precision air circuit modules for ventilators, OEMach easily meets the challenges of multi-variety, small-batch customized orders thanks to the flexible production capabilities of our CNC machining equipment. Throughout the manufacturing process, we maintain strict control over every step, utilizing advanced inspection equipment and systematic management procedures to minimize errors, ensuring both the precision of a diverse range of components and the quality consistency of small-batch production.

With a commitment to professionalism, efficiency, and safety, OEMach is deeply involved in the innovative development of the medical device industry, crafting every component with meticulous attention to detail, safeguarding every heartbeat, and becoming a trusted partner to medical device manufacturers.

Category

Form

Material Process

Processing Materials

Medical-Grade Rubber

Medical-Grade Rubber: Materials such as silicone rubber and polyurethane rubber possess excellent elasticity, flexibility, and biocompatibility, making them suitable for producing medical seals, catheters, balloons, and other components that require safe and stable performance within the human body.

Medical-Grade Plastics

Medical-grade plastics such as polylactic acid (PLA) and polyether ether ketone (PEEK) are characterized by their light weight, ease of processing, and excellent biodegradability or biostability. PLA is commonly used for manufacturing absorbable sutures and other disposable medical devices, while PEEK is employed in the production of advanced orthopedic implants and dental restoration materials, offering long-term stability within the human body

Titanium Alloy

Titanium alloys such as Ti-6Al-4V feature low density, high strength, and exceptional biocompatibility, making them ideal materials for orthopedic implants such as artificial joints and spinal fixation devices. Its outstanding mechanical properties and biocompatibility significantly reduce the risk of rejection after implantation.

Stainless Steel

Stainless steels such as 304 and 316 offer excellent corrosion resistance, strength, and biocompatibility, making them widely used in the production of surgical instruments, medical implants (such as suturing staples and bone screws), and medical device housings. Their ease of machining and stability ensure that components can be used reliably over the long term in complex medical environments.

Application Fields