Industrial Automation

Service Overview

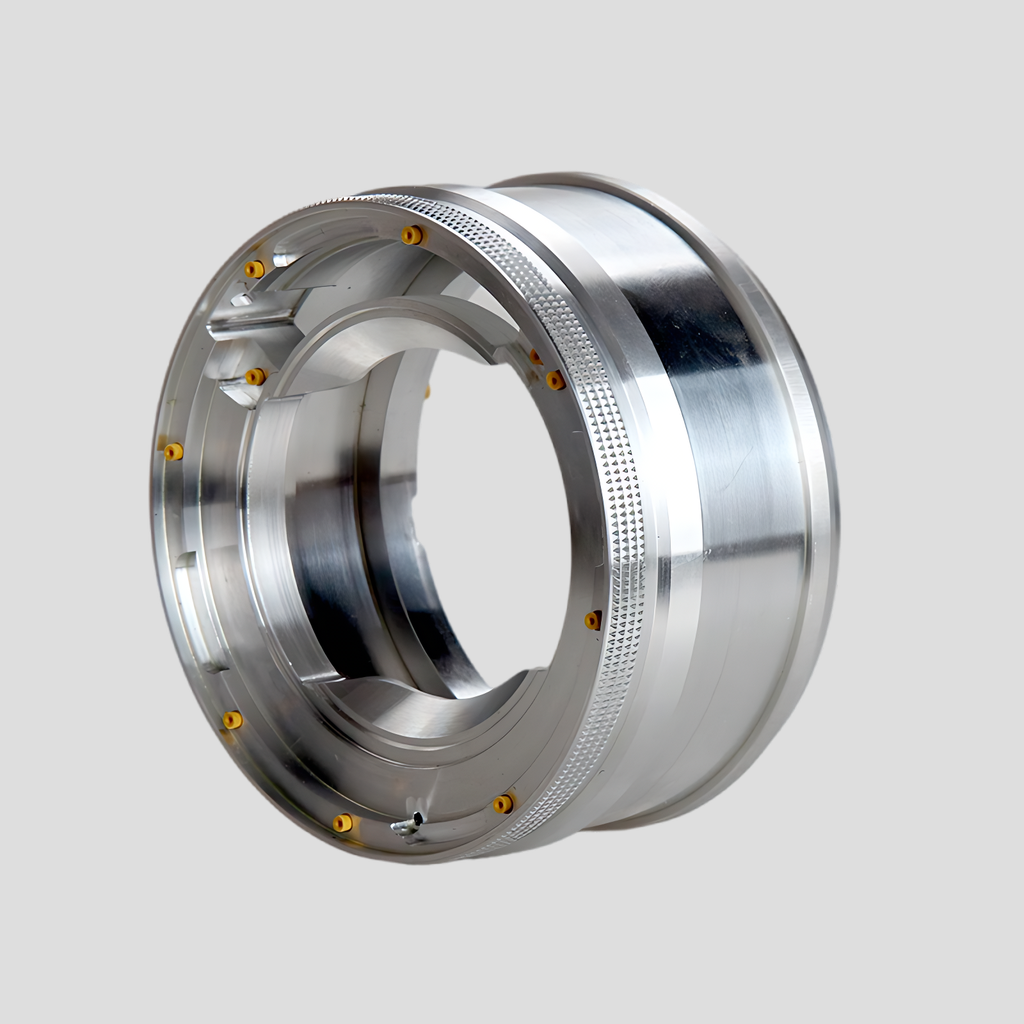

OEMach specializes in the machining of industrial equipment parts, providing high-precision and high-quality manufacturing services for a wide range of industrial equipment. The industrial equipment parts we produce cover mechanical transmission components, automation equipment assemblies, and machine tool parts, ensuring that every part meets stringent industrial standards. With advanced processing equipment and a highly skilled technical team, OEMach is able to meet the customized needs of various clients. From design optimization to finished product delivery, we exercise strict quality control throughout the entire process, supporting the efficient operation of industrial equipment and driving the development of the manufacturing industry.

Category

Form

Material Process

Processing Materials

Engineering Plastics

Materials such as polytetrafluoroethylene (PTFE) and nylon feature low weight, corrosion resistance, and self-lubricating properties. PTFE can be used to produce seals, bearings, and other components to reduce friction. Nylon is used in the manufacturing of gears, pulleys, and similar parts, reducing noise and providing a certain degree of wear resistance. These materials are widely used in industrial equipment where lightweight construction and corrosion resistance are required.

Non-ferrous Metals and Alloys

Aluminum and aluminum alloys are lightweight and highly corrosion-resistant, making them ideal for components in the aerospace and automotive industries, such as aircraft fuselage frames and automotive engine blocks. Copper and copper alloys offer excellent electrical and thermal conductivity and can be used to manufacture motor windings, heat dissipation components, and more. Titanium alloys, with their high strength, low density, and superior corrosion resistance, are used for critical parts in advanced fields such as aerospace and medical devices.

Cast iron

Offers excellent castability, vibration damping, and wear resistance. Gray cast iron is used in the production of machine tool beds, bases, and similar components, leveraging its vibration damping properties to minimize vibrations during machining; ductile cast iron provides better mechanical properties and can replace some cast steel parts, making it suitable for producing high-load components such as automobile hubs and pipe fittings.

Alloy steel

By adding alloying elements such as chromium, nickel, molybdenum, and manganese to carbon steel, alloy steels acquire special properties. For example, chromium-molybdenum alloy steel possesses high strength, good toughness, and high temperature resistance, and is often used to manufacture engine crankshafts and high-pressure valves. Stainless steel (such as 304 and 316) is highly corrosion-resistant and is used for parts exposed to corrosive media, such as those found in food machinery and chemical equipment.

Carbon steel

It is a commonly used material for industrial equipment parts processing, offering relatively low cost and ease of machining. Ordinary carbon steels such as Q235 are used for producing components that do not require high strength, such as brackets and bases; 45 steel, after being subjected to processes like tempering and quenching, exhibits good strength and toughness, making it suitable for manufacturing load-bearing parts such as shafts and gears.

Application Fields