New Energy

Service Overview

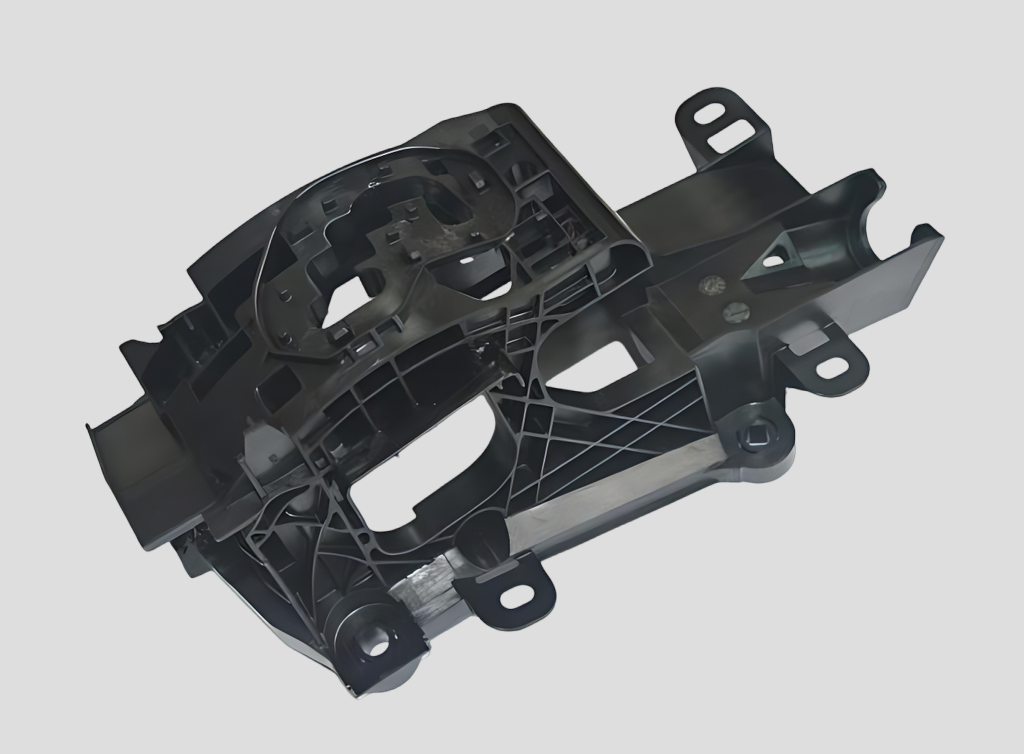

OEMach specializes in the machining of new energy components, supporting the advancement of green energy. We are equipped with state-of-the-art production equipment and a professional technical team, providing customers with high-precision, high-performance component machining services. Whether for electric vehicle battery modules, solar equipment brackets, or critical wind power components, we can ensure both quality and efficiency. Driven by innovation, OEMach rigorously controls every stage of the production process to provide reliable support for the new energy industry and promote sustainable development.

Category

Form

Material Process

Processing Materials

Platinum Group Metals

In hydrogen fuel cells, platinum and other platinum group metals serve as catalysts. Although only small amounts are required, their role is critical. By employing specialized processing techniques, these metals are loaded onto electrode materials, thereby enhancing the electrochemical reaction efficiency of the fuel cell.

Aluminum Alloys

Aluminum alloys are widely used in the field of new energy vehicles and other related sectors. Due to their light weight and excellent corrosion resistance, aluminum alloys are commonly used in the production of battery enclosures, motor housings, and body structural components, helping to reduce the overall vehicle weight and improve energy utilization efficiency.

Carbon Fiber Composites

In the wind energy sector, carbon fiber composites are used to manufacture wind turbine blades. These materials feature a high specific strength and high specific modulus, enabling them to reduce the weight of the blades while maintaining sufficient strength and rigidity, thereby improving wind power generation efficiency.

Silicon

In the field of solar photovoltaics, silicon is the primary material. Monocrystalline and polycrystalline silicon are used to manufacture solar cells. Through a series of processing steps such as cutting, texturing, diffusion, and coating, the photoelectric conversion efficiency of silicon materials is enhanced.

Application Fields