Aerospace

Service Overview

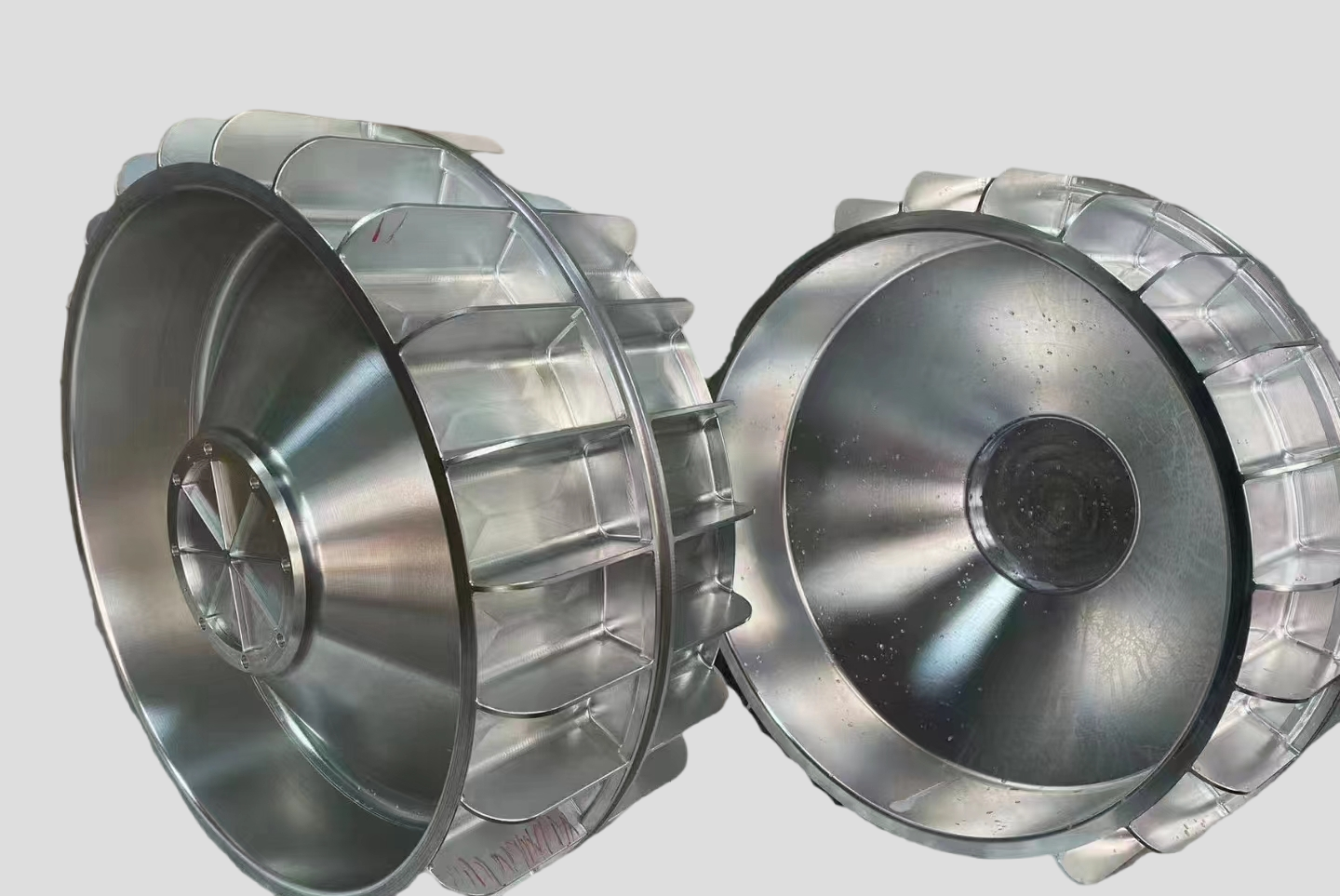

OEMach specializes in the machining of aerospace components, leveraging advanced technologies and rigorous standards to deliver high-precision, high-strength parts for the industry. The aerospace components we manufacture encompass fuselage structural parts, engine components, and more, ensuring that every part meets the stringent requirements of aviation standards. From precision machining to the forming of complex structures, OEMach leverages outstanding craftsmanship and rigorous quality control to support the advancement of aerospace, safeguarding flight safety at every stage.

Category

Form

Material Process

Processing Materials

Carbon fiber composites

With high specific strength, high specific modulus, and strong design flexibility, carbon fiber composites effectively reduce aircraft weight and enhance both fuel efficiency and overall performance. Commonly used in the production of aircraft wings, fuselage structural components, and satellite parts, carbon fiber composites have become integral in aerospace manufacturing. For example, the Boeing 787 utilizes large amounts of carbon fiber composite material, resulting in a significant reduction in overall weight.

High-temperature Alloys

These materials maintain excellent mechanical properties and chemical stability under high temperatures and complex stress environments. Nickel-based high-temperature alloys, such as Inconel 718, are used in the production of turbine blades and combustion chamber components for aircraft engines, ensuring stable performance at temperatures around 1000°C and supporting efficient engine operation.

Aluminum alloys

Lightweight with good formability and corrosion resistance, aluminum alloys are among the most commonly used lightweight materials in the aerospace sector. For instance, 2024 aluminum alloy is widely used for aircraft skins and wing frames, while 7075 aluminum alloy, known for its high strength, is suitable for manufacturing load-bearing parts such as aircraft joints and structural frames.

Titanium alloys

Featuring low density, high strength, excellent high-temperature resistance, and outstanding corrosion resistance, titanium alloys are widely used in aerospace structural components and engine parts. For example, Ti-6Al-4V titanium alloy is utilized in the manufacturing of aircraft landing gear, engine compressor discs, and blades, providing high strength and reliability while minimizing weight.

Application Fields