Years of Experience in Machined Parts Manufacturing

Years of Experience in Machined Parts Manufacturing

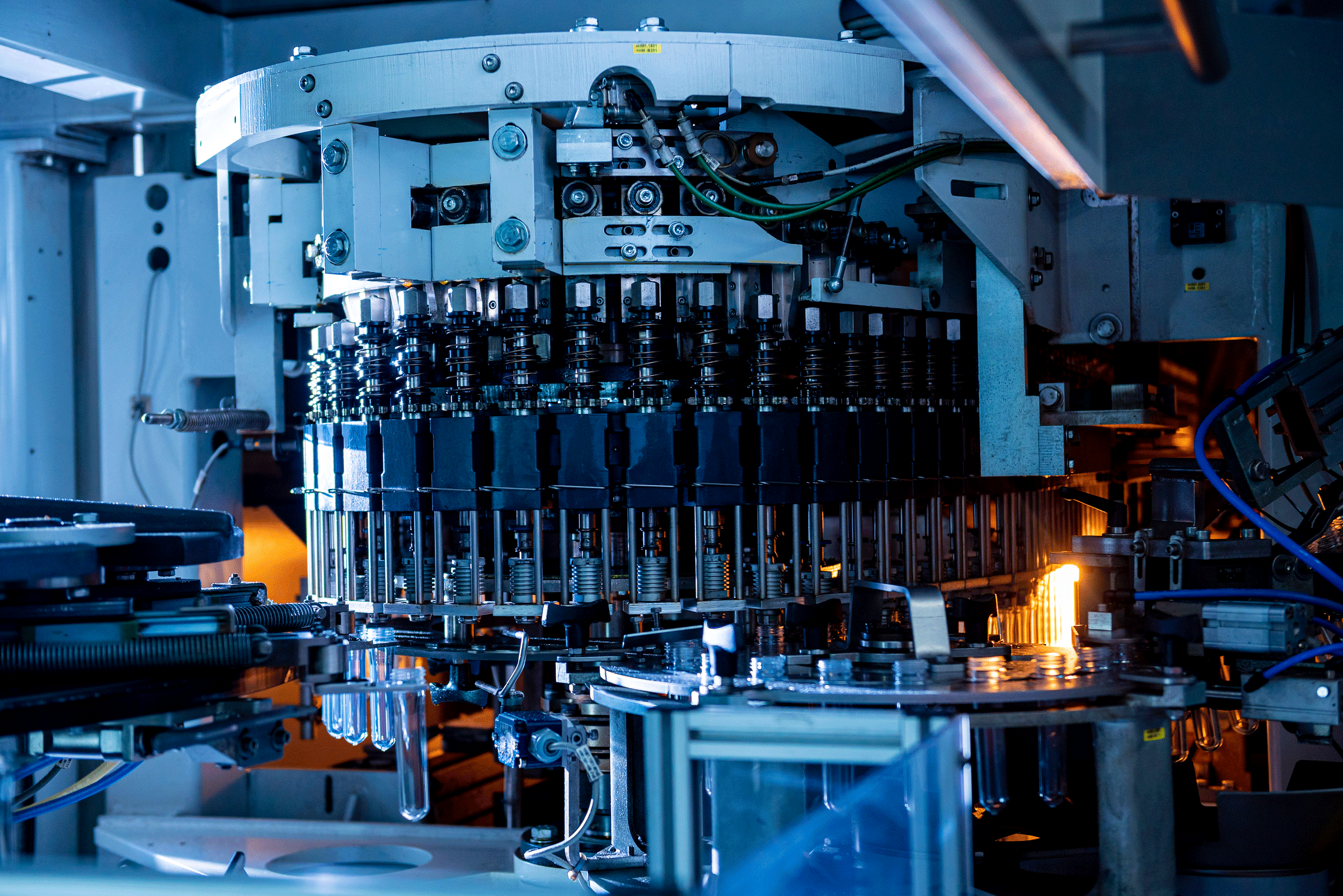

Comprehensive equipment and processes

We are equipped with a wide range of advanced machinery, including turning, milling, grinding, drilling, and CNC machining, providing full-process coverage. Whether for simple parts or complex structures, we offer one-stop solutions to meet diverse machining needs, ensuring both product quality and production efficiency.

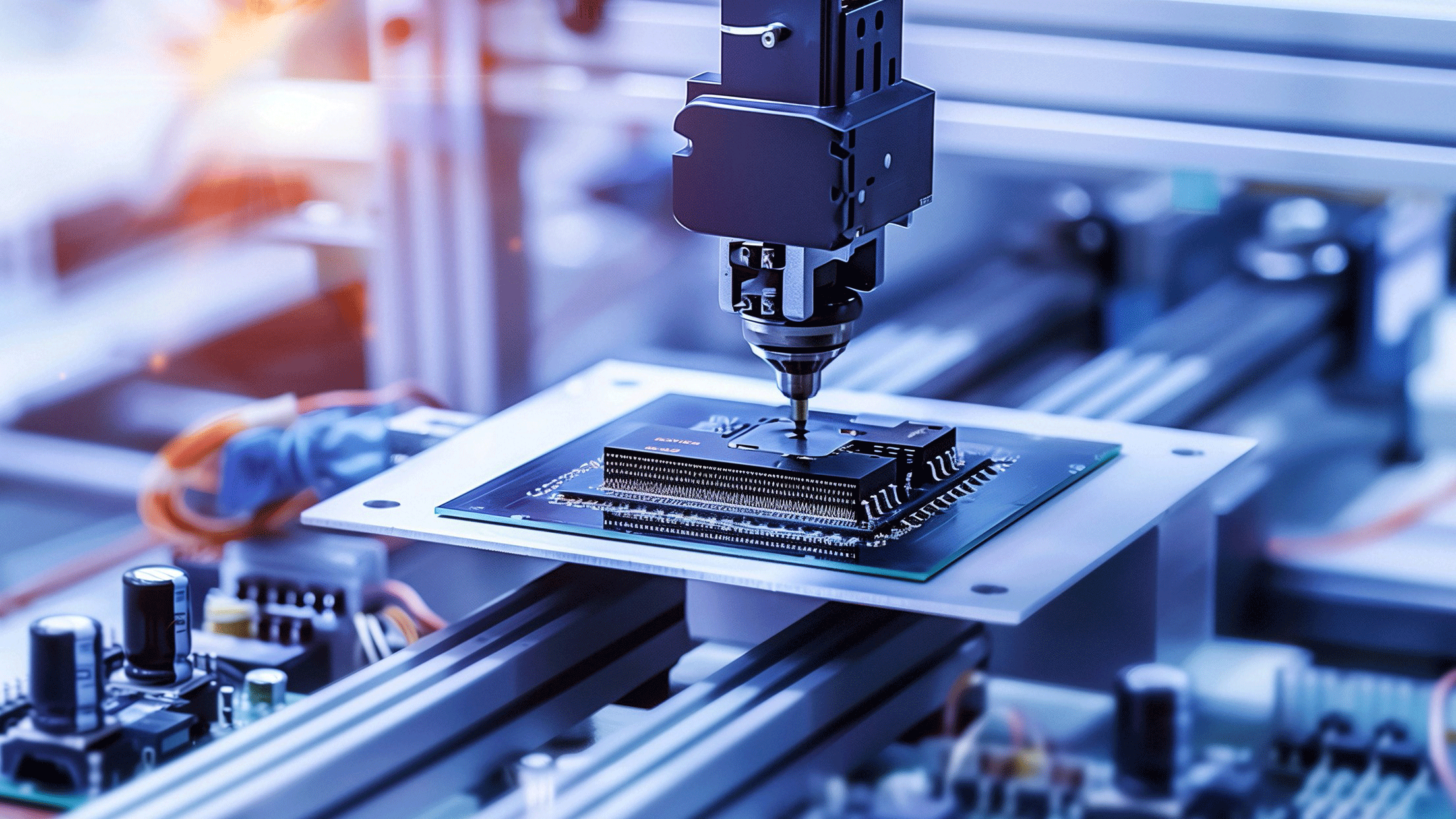

High precision up to 0.005 mm

Utilizing advanced high-precision CNC machines and a rigorous inspection system, we achieve critical dimensional tolerances of ±0.005 mm, meeting the stringent accuracy standards required by high-end fields such as precision instruments, medical devices, and optics.

Small-batch manufacturing

Breaking traditional batch limitations, supporting single-piece customized production, eliminating the need for inventory, and reducing trial-and-error costs. From sample validation to small-batch requirements, we flexibly handle orders to help streamline your R&D and production processes.

5–10 day rapid delivery

Streamlined production processes and a dedicated professional team enable standard parts to be delivered in as fast as 5 days, with rush orders prioritized for expedited processing. Reduced lead times to help you respond quickly to the market and seize new opportunities.

Product Cases

Why Choose Us?

Our Commitment

Choose us with confidence

every micron is a promise

Industry Application

Representative Clients